We offer you

the best Support!

- Reaching for the sky.

Frequently asked questions (FAQ)

We always analyze the questions we receive and have collected the most frequently asked ones here.

If there are still open questions, please create a ticket in our ticket system or simply call us directly.

With the MyXPert® ToolManager package you will experience the simplest resource management in a central database solution for the manufacturing industry. All technical information of your turning/milling tools, testing/measuring equipment, clamping devices or also related material/cutting data are based on international standards and thus let you reach your goal faster. Central know-how of the entire production in combination with a worldwide unique 2D.ID (2D matrix code) can simplify the entire logistics in your warehouse.

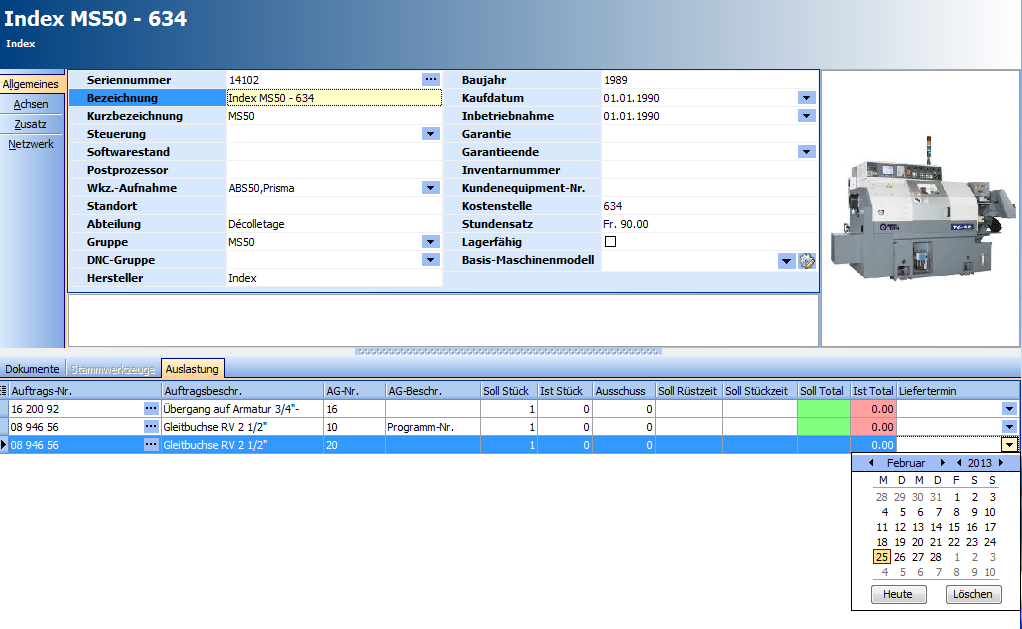

In the “Resources” module, the “Utilization” tab shows all assigned working lengths and their operations in a utilization list.

Experience how easy NC program creation can be with the database-oriented manufacturing software SprutCAM PDM. From milling of 2 to 5 axes simultaneously, turning, long turning, wire eroding and robotics, your entire machining production can be programmed and controlled in a control-neutral way. The integrated machine workspace simulation allows a detailed, monitored display of the respective traverse paths interactively on your PC, thus drastically reducing the run-in and set-up time.

During installation, the MyXPert Launcher application is placed on your Windows desktop. There you will find numerous tutorial videos under the YouTube icons. These explain the most important steps in programming with the CAM system.

The machining result can be exported as a stl. file in the Simulation window by right-clicking the mouse, Simulation, Save simulation result. The simulation method should be set to solid, otherwise a very large file will be created.

The programming language of the post-processor generator is a Pascal-like but nevertheless proprietary programming language. We are happy to offer you training in this area according to our well-known models: coaching@web, coaching@class and coaching@customer.

If you are interested, you can contact us via contact form or directly via e-mail!

The workpiece is outside of the screen view, with the function “area fitting” the workpiece is automatically centered in the screen center. It is also possible that the “Model geometry visible” function is switched off.

CustomData(“<ItemName>”)

The following example shows the use of the command (highlighted in red):

program PPFun

iTeethCount: Integer;

IF (cld[1] = 58) THEN

BEGIN

iTeethCount = Cmd.Int[“PPFun(TechInfo).Operation(1).ToolSection.Tools(1).Properties.TeethCount”];

output “Teeth count for current tool: ” + Str(iTeethCount);

END;

end;

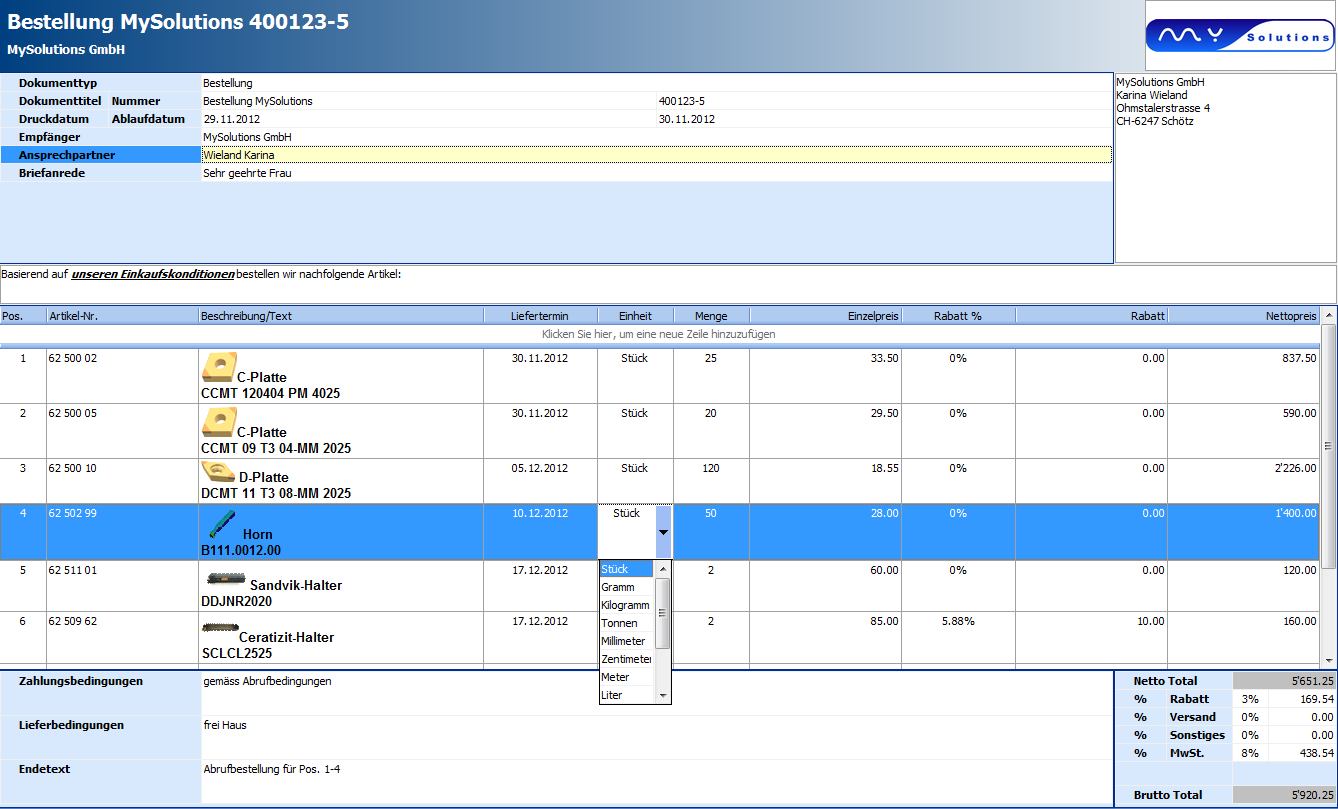

Convenient, simple, fast and efficient, you can get a grip on the enterprise resource planning (WMS) in your production company with the MyXPert® OfficeManager. For example, as a contract manufacturer you can easily create the pre-/post calculations for your quotations, delivery notes and invoices of the production orders with fully integrated address and contact management (CRM). The automatic order proposal module helps you with important stock levels, so that you never run into a bottleneck with important products, e.g. for a product manufacturer, or even standard parts, raw materials. Alternatively, you can simply work Just-In-Time.

For each article, different suppliers and also individual price adjustments such as graduated, flat-rate or base prices or even combinations of these can be created. Individual price adjustment

With the MyXPert® ToolManager package you will experience the simplest resource management in a central database solution for the manufacturing industry. All technical information of your turning/milling tools, testing/measuring equipment, clamping devices or also related material/cutting data are based on international standards and thus let you reach your goal faster. Central know-how of the entire production in combination with a worldwide unique 2D.ID (2D matrix code) can simplify the entire logistics in your warehouse.

In the interactive tool assembly with the ToolGenerator, multiple design is also supported. By simple drag & drop you can define the orientation and also by mouse the number, the offset values, rotations etc. for the cutting body. The complete tool is thus loaded fully automatically. Automatic tool loading

Only data that is up-to-date can be planned and controlled. With our MyXPert® Monitoring Software Package we monitor (SCADA) your machines and plants by integration of the PLC/PLC in real time and can make intelligent predictions such as predictive maintenance (CMMS) in combination with the necessary set-up times according to your production planning (PPS). Even test and measuring equipment is subject to test cycles in order to always be accurate and remain operational. You can achieve exactly this through central scheduling. You will always be reminded in time of your deadline work and can thus concentrate on your optimal work processes.

With the integrated light bars and up-to-date hardware performance, this industrial touch PC is suitable for a very wide range of applications.

A faster reaction/information, even if you are NOT standing directly in front of the terminal. Similar function to the signal lights on production machines. Each animation can be assigned to an activity or a status, thus attracting the attention of the operator.

The traffic light concept is basically integrated here: Red = error, yellow = attention, green = note, blue = alarm. The colours can be animated as a supporting effect; examples: Flashing = urgent, from bottom to top = upload, from top to bottom = download etc. Can be programmed specifically for each application.

With the integrated light bars and up-to-date hardware performance, this industrial touch PC is suitable for a very wide range of applications.

In order to be able to retrofit existing components, e.g. tools with a data carrier bore according to DIN. In combination with the MyXPert ToolManager database a very often used addition. The tags are already lasered with a 2D.ID code and delivered.