More intelligent solutions

for more freedom!

- Reaching for the sky.

MyXPert® ToolManager

& your benefits!

Tool Management (TDM)

2D/3D - Digital twin

Each article can be assigned to a 2D and 3D CAD file for simulation purposes and for transfer to third-party programs. These data are graphically displayed directly in the ToolManager and can also be edited individually. The automatic assembly of complete tools is done graphically and interactively directly via logically predefined assembly points.

Administration

In addition to the technical area, it is possible to manage all created articles on the commercial side. For each article, information important for production and purchasing such as stock details, warehouse information or order conditions can be documented.

DIN 4000 / ISO 13399

Based on the DIN-4000/ISO-13399 structures, the logical separation point coding is very simple. Many data can be transferred directly from tool catalogs or other sources. The DIN-4000/ISO-13399 structures already describe a large number of tool parameters and map them directly in the ToolManager.

«Your manufacturing solution that not only combines technology and logistics, but also brings them to life!»

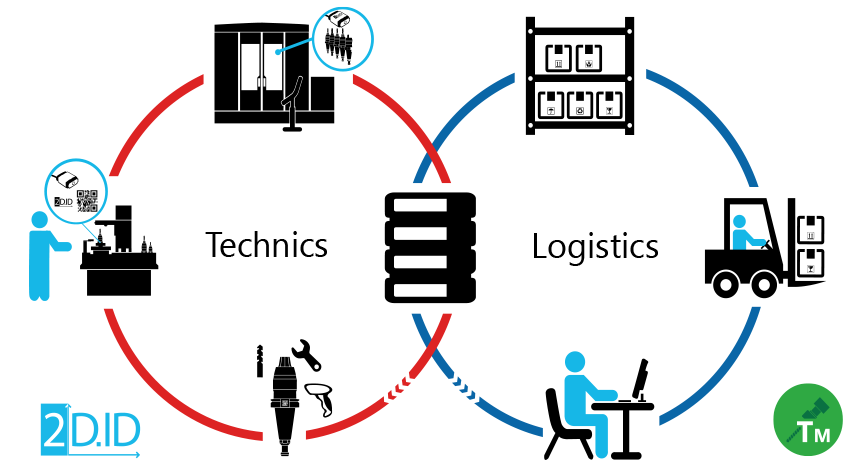

Cycle - Technics and logistics

Technics

The technical master data in the red circle describe the tool components by their geometric properties, design and possible uses. The information is structured into the actual description of the tools based onspecification parameters according to DIN-4000 / ISO-13399.All data describe a cutting tool from a technical point of view without taking its availability into account.

Logistics

The logistical movement data in the blue cycle refers to the requirements planning, the stock and the storage location of the tools. It covers the complete warehousing and procurement of theindividual parts. In this way, the movements (so-called tracking) of the assembled cutting tools can also be planned and monitored.

More All-In-One solutions

2D/3D graphics

The MyXPert® ToolManagement Software contains a tool catalogue including the corresponding digital tool twins for simulations, collision analysis, planning etc.

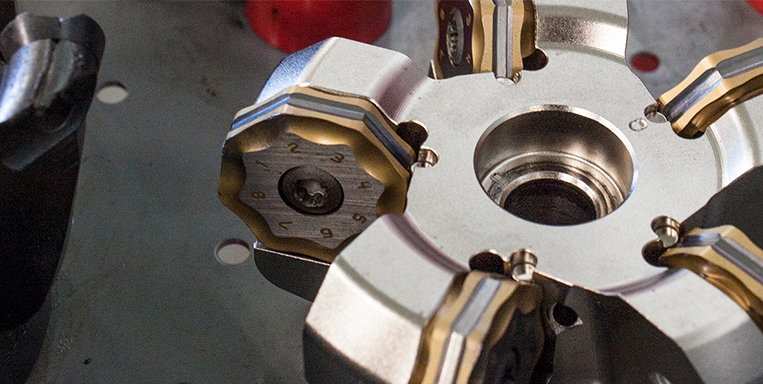

Complete tool

In order to obtain a cutting tool, several individual parts are required. Thanks to the DIN-4000 structure, these individual parts are there defined, described and mapped in according to the known standard.

DIN4000 / ISO13399

DIN 4000 / ISO 13399 structures already define, describe and map a large number of tool parameters. The standardized structure saves a lot of time.

Database

With the MyXPert® ToolManager database solution, your data are centrally stored in one place. Several operators working on the data enables a cross-over information.

Operating resources Administration

In addition to the tool catalogue, further resources can be managed in the MyXPert® ToolManager such as: oils, greases, measuring equipment, protective clothing etc.

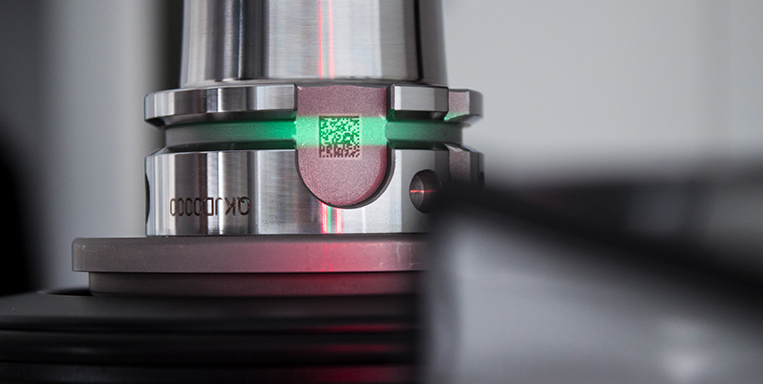

2D.ID - Tool identification

With the unique MyXPert® tool identification "2D.ID" from MySolutions AG, you can track your tools, store histories and find them quickly at any time.

MyXPert ® ToolManager

| Module / Features | MyXPert® OfficeManager | MyXPert® ProductionManager | MyXPert® ToolManager |

|---|---|---|---|

| Adressen (Kunden, Lieferanten etc.) / Addresses (customers, suppliers etc.) | ✓ | ✓ | ✓ |

| Ressourcen (CNC-Maschinen, Handarbeitsplätze etc.) / Resources (CNC machines, manual workstations etc.) | - | ✓ | ✓ |

| Artikel (Logistische Daten mit Preisen, Lagerorten etc.) / Articles (Logistical data with prices, storage locations etc.) | ✓ | ✓ | ✓ |

| Arbeitspläne (Vorlagen, Produktionsaufträge etc.) / Work plans (templates, production orders etc.) | - | ✓ | ✓ |

| Fakturamodul / Invoice Module | ✓ | option | option |

| Reports (Arbeitspläne, Lagerentnahmelisten etc.) / Reports (routings, stock picking lists etc.) | ✓ | ✓ | ✓ |

| Reports, Angebot – Rechnung / Anfrage – Bestellung etc. / Reports, offer - invoice / inquiry - order etc. | ✓ | - | option |

| Reports (Einrichteblätter, Werkzeugmontagelisten etc.) / Reports (set-up sheets, tool assembly lists etc.) | - | - | ✓ |

| Komplettwerkzeuge und Werkzeugkomponenten / Complete tools and tool components | - | - | ✓ |

| 2D/3D CAD manueller, halb-/vollautomatischer Zusammenbau / 2D/3D CAD manual, semi/fully automatic assembly | - | - | ✓ |

| Reports (Grafische Werkzeugmontagelisten, Ablauflayouts etc.) / Reports (graphical tool assembly lists, process layouts etc.) | - | - | ✓ |

| 2D.ID Technologie für einzelne Komponenten und Baugruppen / 2D.ID technology for individual components and assemblies | - | option | ✓ |

| Werkzeugbeschaffung (Lieferantenanfragen, -bestellungen etc.) / Tool purchasing (supplier enquiries, orders, etc.) | option | ||

| Vollständige Lagerbewirtschaftung / Complete inventory management | option | option | option |

| Wartungsverwaltung (Monitoring) mit eSignature Unterstützung / Maintenance management (monitoring) with eSignature support | - | option | option |